Veterinary anesthesia equipment defines how safely and consistently patients can be anesthetized

Veterinary anesthesia equipment is the integrated system of machines, breathing circuits, vaporizers, gas delivery components, and monitoring devices used to induce and maintain anesthesia in animals. Its primary function is to deliver precise anesthetic concentrations while supporting respiration and cardiovascular stability. Equipment quality directly influences patient safety, workflow efficiency, and clinical confidence.

Modern veterinary anesthesia equipment is no longer a single machine but a coordinated platform. It must function reliably across species, sizes, and procedures while minimizing human error. Clinics evaluating equipment are ultimately evaluating risk control as much as clinical capability.

A modern veterinary anesthesia machine is built around controlled gas delivery

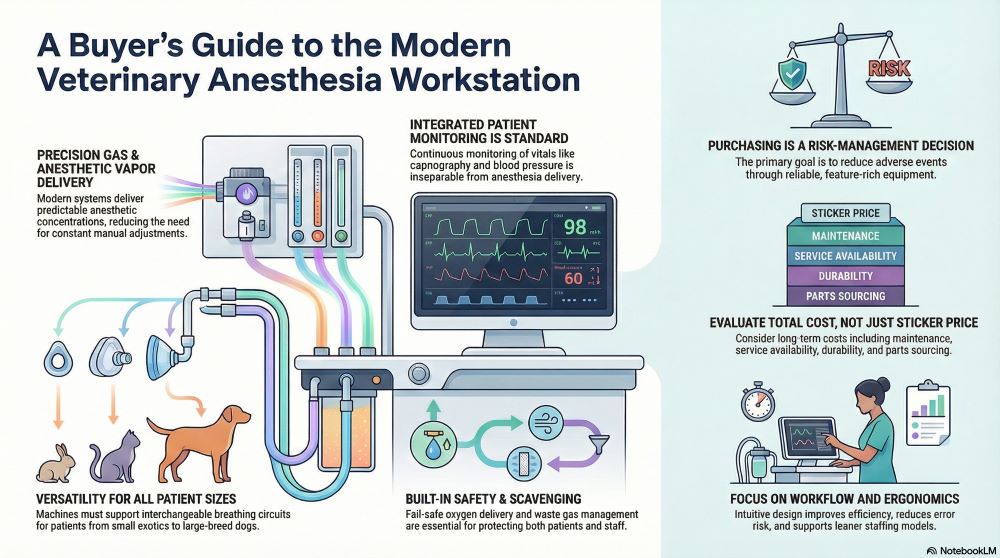

At the center of veterinary anesthesia equipment is the anesthesia machine responsible for delivering oxygen and anesthetic gases at predictable concentrations. Modern systems emphasize precision, redundancy, and ease of adjustment during procedures. Consistent gas flow under varying conditions is a baseline requirement.

Unlike older designs, contemporary machines reduce reliance on manual estimation. Flowmeters, pressure regulators, and vaporizers are engineered to maintain stability even with changes in patient ventilation. This predictability supports safer anesthesia management across routine and complex cases.

Veterinary anesthesia equipment must support patients of widely varying sizes

Veterinary practices anesthetize animals ranging from small exotics to large-breed dogs. Anesthesia equipment must accommodate these extremes without compromising accuracy. Dead space, resistance, and tidal volume adaptability become critical considerations.

Modern machines address this by supporting interchangeable breathing circuits and adjustable flow parameters. Pediatric and non-rebreathing configurations are just as important as large-volume circle systems. Versatility ensures one platform can safely support the full caseload.

Anesthesia vaporizers determine dosing accuracy and stability

Vaporizers control how liquid anesthetic agents are converted into precise vapor concentrations. Accuracy at low flow rates is particularly important in veterinary settings. Poor vaporizer performance increases the risk of under- or over-anesthetizing patients.

Modern veterinary anesthesia equipment uses agent-specific, temperature-compensated vaporizers. These designs maintain stable output despite ambient temperature changes or prolonged use. Reliable vaporizers reduce the need for constant manual correction during procedures.

Precision vaporization reduces clinician workload

Stable vaporizer output allows clinicians to focus on patient monitoring rather than constant gas adjustments. Reduced variability translates into smoother anesthetic planes. This consistency improves procedural efficiency and patient recovery outcomes.

Oxygen delivery reliability is non-negotiable in anesthesia systems

Oxygen is the foundational gas in veterinary anesthesia. Equipment must deliver uninterrupted oxygen flow under all operating conditions. Any failure in oxygen delivery represents an immediate patient safety threat.

Modern machines incorporate fail-safe mechanisms that prevent hypoxic gas mixtures. Oxygen flush valves, pressure relief systems, and alarmed flow monitoring reduce risk. Redundancy in oxygen delivery components is a defining feature of contemporary equipment.

Breathing circuits influence ventilation efficiency and patient safety

Breathing circuits connect the anesthesia machine to the patient and directly affect resistance and gas exchange. Circuit selection must match patient size, lung capacity, and procedure length. Improper circuit choice increases work of breathing and CO₂ retention.

Veterinary anesthesia equipment typically supports both rebreathing and non-rebreathing circuits. Rebreathing systems improve gas efficiency for larger patients, while non-rebreathing circuits minimize resistance for small animals. Flexibility in circuit configuration is essential.

CO₂ absorption systems support prolonged anesthesia

In rebreathing systems, CO₂ absorbers prevent carbon dioxide buildup. Modern absorbers are designed for easy inspection and replacement. Clear housings and ergonomic canisters improve safety and workflow.

Waste anesthetic gas management protects staff and facilities

Anesthesia equipment must control waste anesthetic gas exposure. Chronic exposure poses occupational health risks and regulatory concerns. Effective scavenging is therefore a core requirement, not an optional add-on.

Modern veterinary anesthesia equipment integrates passive or active scavenging connections. Properly designed exhaust pathways prevent gas accumulation in procedure rooms. Clinics evaluating equipment should assess scavenging compatibility with their facility layout.

Anesthesia monitoring equipment is inseparable from anesthesia delivery

Veterinary anesthesia equipment now assumes continuous monitoring as standard practice. Monitoring systems track vital parameters that reflect anesthetic depth and physiological stability. Without monitoring, anesthesia delivery becomes guesswork.

Core monitoring typically includes heart rate, respiratory rate, oxygen saturation, blood pressure, and carbon dioxide levels. These measurements provide early warning of instability. Integration between anesthesia machines and monitors improves situational awareness.

Capnography provides real-time ventilation insight

Capnography measures exhaled carbon dioxide and offers immediate feedback on ventilation status. In veterinary anesthesia, it is one of the most reliable indicators of respiratory compromise. Sudden changes often precede clinical signs.

Modern anesthesia monitoring equipment integrates capnography into multi-parameter monitors. Clear waveform display and numeric values support rapid interpretation. Capnography reduces the likelihood of unnoticed apnea or circuit disconnections.

Pulse oximetry supports oxygenation assessment

Pulse oximetry estimates arterial oxygen saturation and remains a cornerstone of anesthesia monitoring. It provides continuous, non-invasive feedback. While not a substitute for ventilation monitoring, it adds critical context.

Modern veterinary monitors improve signal quality through motion-resistant sensors and species-adapted algorithms. Reliable readings across different animal types enhance clinical confidence. Pulse oximetry supports safer anesthetic management when used alongside other parameters.

Blood pressure monitoring informs perfusion status

Blood pressure trends reveal how well tissues are being perfused during anesthesia. Hypotension is a common anesthetic complication with serious consequences. Early detection allows timely intervention.

Veterinary anesthesia monitoring equipment supports non-invasive and invasive blood pressure measurement. Non-invasive systems are commonly used for routine procedures. Accuracy and cuff compatibility across species are key evaluation criteria.

Integrated monitoring improves response time during anesthesia events

When monitoring data is centralized, clinicians can detect patterns rather than isolated abnormalities. Integrated displays reduce cognitive load during critical moments. Faster recognition leads to faster intervention.

Modern anesthesia workstations increasingly consolidate monitoring into unified interfaces. Alarms are configurable to clinical preferences. Integration supports safer workflows in high-volume or understaffed environments.

Equipment ergonomics influence procedural efficiency

Anesthesia equipment design affects how clinicians interact with the system during procedures. Poorly arranged controls or displays increase error risk. Ergonomics matter in both routine and emergency scenarios.

Modern veterinary anesthesia equipment emphasizes intuitive layouts and logical control grouping. Touchpoints are positioned for easy access without breaking sterile fields. Efficient design supports smoother procedural flow.

Equipment durability matters in clinical environments

Veterinary clinics demand equipment that tolerates frequent cleaning, movement, and long operating hours. Fragile components increase downtime and service costs. Durability is therefore a practical purchasing criterion.

Modern anesthesia machines are built with reinforced frames and sealed components. Materials are selected to withstand disinfectants and repeated handling. Durability protects both investment value and clinical availability.

Maintenance requirements shape long-term ownership costs

Anesthesia equipment requires routine inspection, calibration, and component replacement. Systems with complex maintenance demands increase operational burden. Simpler service requirements improve long-term usability.

Modern veterinary anesthesia equipment often features modular components. Vaporizers, absorbers, and circuits can be serviced or replaced independently. Modular design reduces downtime and simplifies inventory management.

Compatibility with existing clinic infrastructure matters

Anesthesia equipment must integrate with a clinic’s oxygen sources, scavenging systems, and electrical capacity. Poor compatibility creates additional installation costs. Evaluation should extend beyond the machine itself.

Modern systems are designed for flexible integration with central oxygen lines or portable tanks. Electrical requirements are standardized for typical clinical settings. Compatibility reduces barriers to adoption.

Veterinary anesthesia equipment must support regulatory compliance

While specific requirements vary by region, anesthesia equipment must align with professional standards of care. Monitoring capabilities, scavenging support, and safety features are increasingly expected. Compliance protects both patients and practices.

Modern equipment reflects these expectations through built-in safety mechanisms. Alarms, fail-safes, and monitoring integration support defensible clinical practices. Compliance becomes embedded rather than retrofitted.

Species diversity increases anesthesia equipment complexity

Veterinary practices anesthetize species with different respiratory physiology and drug responses. Equipment must accommodate these differences without excessive manual adjustment. Flexibility is therefore essential.

Modern veterinary anesthesia equipment supports configurable settings and interchangeable components. This adaptability allows clinicians to tailor anesthesia delivery to species-specific needs. Versatility reduces equipment redundancy.

Anesthesia machines influence recovery quality

Recovery quality is influenced by anesthetic precision and monitoring quality. Overexposure or delayed detection of instability prolongs recovery times. Equipment performance therefore affects post-operative outcomes.

Modern systems support low-flow anesthesia and precise vaporization. These capabilities reduce anesthetic accumulation and support smoother recoveries. Improved recovery outcomes enhance patient safety and client satisfaction.

Training and usability affect equipment effectiveness

Even advanced equipment fails if users cannot operate it confidently. Veterinary anesthesia equipment should support intuitive learning curves. Clear labeling and logical interfaces reduce training time.

Modern manufacturers prioritize user-centered design. Consistency across models supports familiarity and reduces errors. Usability enhances both safety and efficiency.

Data visibility improves anesthesia decision-making

Access to clear, real-time data enables better anesthesia management. Trends are often more informative than single readings. Equipment that highlights trends improves situational awareness.

Modern monitoring equipment displays trend graphs alongside numeric values. This visualization supports proactive adjustments. Better data visibility leads to better clinical decisions.

Scalability supports clinic growth

As practices expand, anesthesia equipment must scale with procedural volume and complexity. Systems that limit expansion create future constraints. Scalability should factor into purchasing decisions.

Modern veterinary anesthesia equipment supports add-on monitors, expanded circuit options, and procedural upgrades. Scalability protects long-term investment value. Growth-ready equipment aligns with practice evolution.

Veterinary anesthesia equipment purchasing is a risk-management decision

Selecting anesthesia equipment is fundamentally about managing clinical risk. Equipment reliability, monitoring depth, and safety features reduce adverse events. Risk mitigation is the underlying value proposition.

Modern equipment reflects this reality by prioritizing redundancy and monitoring integration. Clinics that invest in robust systems reduce uncertainty. Risk management drives better outcomes.

Cost evaluation of veterinary anesthesia equipment in Canada extends beyond sticker price

For Canadian clinics, the true cost of veterinary anesthesia equipment is shaped by longevity, service access, and operational efficiency rather than initial purchase alone. Import timelines, currency exposure, and service availability can materially affect long-term ownership. Equipment that appears cost-effective upfront may carry higher downstream risk.

Clinics benefit when anesthesia systems are designed for durability and predictable upkeep. Reduced downtime protects procedural schedules and revenue stability. Long-term value matters more than short-term savings.

Service availability within Canada affects equipment reliability

Veterinary anesthesia equipment must be supported by service infrastructure that operates within Canada. Delayed access to technicians or replacement parts can disrupt surgical schedules for extended periods. Cross-border service dependencies introduce avoidable risk.

Modern equipment emphasizes modular components that can be serviced or replaced locally. Vaporizers, absorbers, and monitoring modules should be accessible without extended shipping delays. Canadian clinics prioritize systems that keep operating rooms functional.

Parts sourcing and regulatory alignment influence purchasing decisions

Canadian buyers must account for equipment compatibility with domestic standards and supply chains. Replacement parts that require international sourcing can introduce customs delays and unpredictable timelines. Local availability improves operational confidence.

Equipment that aligns cleanly with Canadian regulatory expectations simplifies compliance. Built-in safety features and monitoring capabilities reduce the need for retroactive upgrades. Compliance readiness protects both patients and practices.

Standardized equipment supports multi-clinic and regional operations

Veterinary groups operating across provinces benefit from standardized anesthesia equipment. Consistency across locations simplifies training, maintenance, and quality control. Standardization also improves staff mobility within regional clinic networks.

When equipment interfaces and monitoring layouts are consistent, teams adapt faster. Emergency response improves when staff encounter familiar systems. Standardization reduces operational friction across geographically dispersed clinics.

Staffing efficiency matters in Canadian veterinary practices

Many Canadian clinics operate with lean staffing models, particularly outside major urban centres. Veterinary anesthesia equipment that requires constant manual oversight increases operational strain. Efficient systems support better allocation of technician time.

Modern equipment stabilizes gas delivery and integrates monitoring, reducing the need for continuous intervention. This efficiency allows staff to focus on patient assessment and recovery. Predictable equipment performance supports safer workflows.

Workflow efficiency supports clinic sustainability

Anesthesia equipment affects how smoothly procedures are scheduled and completed. Slow setup or complex adjustments reduce daily caseload capacity. Over time, these inefficiencies impact clinic sustainability.

Modern veterinary anesthesia equipment supports faster case turnover through intuitive controls and streamlined setup. Improved room utilization benefits clinics managing growing demand. Workflow efficiency becomes an operational advantage.

Environmental considerations are increasingly relevant in Canada

Canadian clinics are placing greater emphasis on environmental responsibility. Low-flow anesthesia capability reduces anesthetic gas consumption and waste. This aligns with both cost control and environmental stewardship.

Modern equipment supports accurate low-flow operation without sacrificing patient safety. Reduced gas usage also lessens the load on scavenging systems. Environmental efficiency increasingly factors into purchasing decisions.

Equipment scalability supports evolving Canadian practice models

As Canadian veterinary practices expand services, anesthesia demands evolve. Equipment must support dentistry, diagnostics, and advanced surgical procedures without frequent replacement. Scalability protects long-term investment value.

Modern systems adapt to a wide range of procedures and patient profiles. This flexibility allows clinics to grow without operational constraints. Scalable equipment supports sustainable practice development.

Predictable performance improves clinical confidence

Consistent anesthesia delivery enables clinicians to make informed decisions based on patient response rather than equipment variability. Predictability reduces stress during complex cases. Confidence in equipment supports confidence in care.

Modern veterinary anesthesia equipment is engineered for stable performance across extended use. Reliability strengthens clinical judgment and patient outcomes. Predictability remains a defining expectation for Canadian buyers.

How BOMImed supports modern veterinary anesthesia needs

BOMImed focuses on veterinary anesthesia equipment that aligns with contemporary clinical expectations and real-world practice demands. The company emphasizes systems designed for precision, safety, and long-term reliability. Clinics evaluating anesthesia machines benefit from equipment that integrates delivery and monitoring into cohesive platforms.

BOMImed’s anesthesia gas machines are selected to support consistent performance across species and procedure types. Attention to durability, serviceability, and compatibility reflects practical clinical priorities. The result is equipment that supports confident anesthesia management rather than complicating it.

FAQ’s

What is included in veterinary anesthesia equipment?

Veterinary anesthesia equipment includes anesthesia machines, vaporizers, breathing circuits, gas delivery components, scavenging systems, and anesthesia monitoring equipment.

Why is monitoring essential during veterinary anesthesia?

Monitoring provides continuous insight into vital functions such as respiration, oxygenation, and circulation. It allows early detection of anesthetic complications.

How does veterinary anesthesia equipment differ from human systems?

Veterinary equipment must accommodate a wider range of patient sizes and species. Circuit flexibility and dosing adaptability are more critical.

What features define a modern veterinary anesthesia machine?

Modern machines emphasize precise gas delivery, fail-safe oxygen systems, integrated monitoring compatibility, and ergonomic design.

Is scavenging required for veterinary anesthesia equipment?

Scavenging is essential to manage waste anesthetic gases and protect staff from chronic exposure. Modern equipment supports scavenging integration.

How often does anesthesia equipment require maintenance?

Maintenance schedules vary by component, but regular inspection and calibration are required. Modular designs simplify ongoing service.

Can one anesthesia machine support multiple species?

Yes, modern veterinary anesthesia machines are designed to support multiple species through adjustable circuits and flow configurations.