Updated 4/1/2025

Anesthesia machines are crucial tools in modern medicine, ensuring patient safety during surgical procedures. These sophisticated devices combine technology, precision, and safety mechanisms to deliver anesthetic agents and manage ventilation effectively. This comprehensive guide will help healthcare professionals understand the key components, functions, and best practices for using anesthesia machines.

What Are Anesthesia Machines?

Anesthesia machines deliver a controlled mix of oxygen, anesthetic agents, and medical gases to maintain patient sedation and oxygenation during surgeries or diagnostic procedures. Their design ensures patient safety while optimizing surgical efficiency.

The evolution of anesthesia machines began in the early 20th century with the Boyle’s machine, which focused solely on delivering gases. Modern devices integrate advanced features such as ventilators, real-time monitoring systems, and safety alarms to reduce human error and improve outcomes. Today, they are essential in operating rooms, ICUs, and even remote medical facilities.

The Importance of Anesthesia Machines

Anesthesia machines are vital for several reasons:

- Ensuring Patient Safety: By delivering precise amounts of oxygen and anesthetic agents, they minimize the risks of under- or over-sedation.

- Environmental Efficiency: Modern machines are designed to recycle gases, reducing environmental impact.

- Versatility: They adapt to various medical scenarios, from routine surgeries to emergencies.

Components of Anesthesia Machines

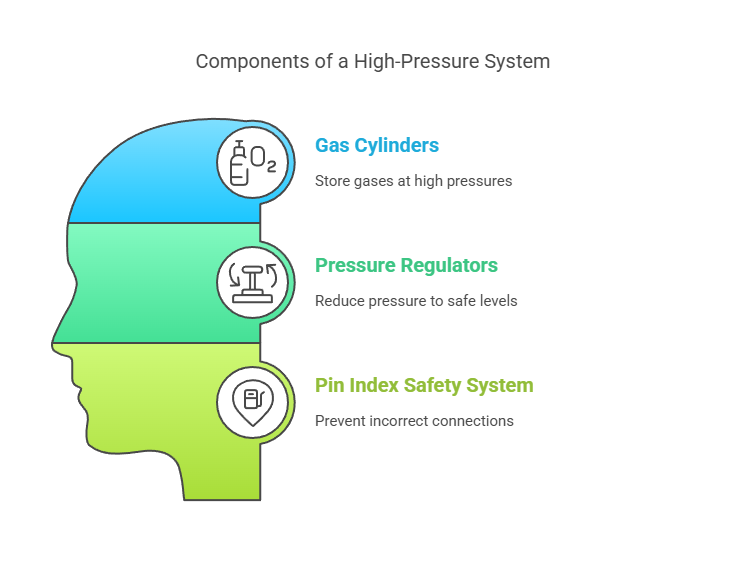

High-Pressure System

The high-pressure system is critical for emergency situations when the main gas supply is unavailable. It consists of:

- Gas Cylinders: Commonly oxygen and nitrous oxide, stored at pressures up to 2200 psi. These provide a backup gas supply.

- Pressure Regulators: Reduce the high pressure from cylinders to a safe level of 45 psi.

- Pin Index Safety System (PISS): Prevents incorrect cylinder connections, ensuring the right gas is delivered.

Intermediate Pressure System

The intermediate system handles gases from the pipeline supply and cylinders, maintaining consistent pressure and flow. Components include:

- Pipeline Inlets: Connect to the hospital’s central gas supply system, delivering oxygen, nitrous oxide, and air at 50 psi.

- Flowmeters: Allow precise adjustments to gas flow, ensuring optimal delivery to the patient.

- Safety Valves: Maintain pressure stability and prevent backflow.

Low-Pressure System

The low-pressure system is where gases are mixed and prepared for patient delivery. Key components are:

- Vaporizers: Convert liquid anesthetic agents like isoflurane and sevoflurane into vapor for inhalation.

- Fresh Gas Outlet: Delivers the final gas mixture to the patient.

- Breathing Circuits: Include adjustable pressure-limiting valves and carbon dioxide absorbers, which recycle exhaled gases.

Understanding the Circle Breathing System

The circle system is a widely used breathing circuit that efficiently manages gas delivery and recycling. It conserves resources, reduces environmental waste, and maintains patient safety. In this system, gases flow through the inspiratory limb to the patient and return via the expiratory limb. A carbon dioxide absorber removes CO2 from exhaled gases, which are then mixed with fresh gas and reintroduced into the system.

Benefits of the Circle System

- Cost Efficiency: Reduces the need for high-flow gas delivery.

- Patient Comfort: Maintains warmth and moisture in the breathing gases.

- Safety: Ensures consistent anesthetic delivery with minimal environmental leakage.

Advanced Features in Modern Anesthesia Machines

Integrated Monitoring Systems

Modern anesthesia machines incorporate real-time monitoring for:

- Vital Signs: Heart rate, oxygen saturation, and blood pressure are displayed continuously.

- Gas Levels: Inspired and expired gas concentrations are monitored to ensure precise anesthetic delivery.

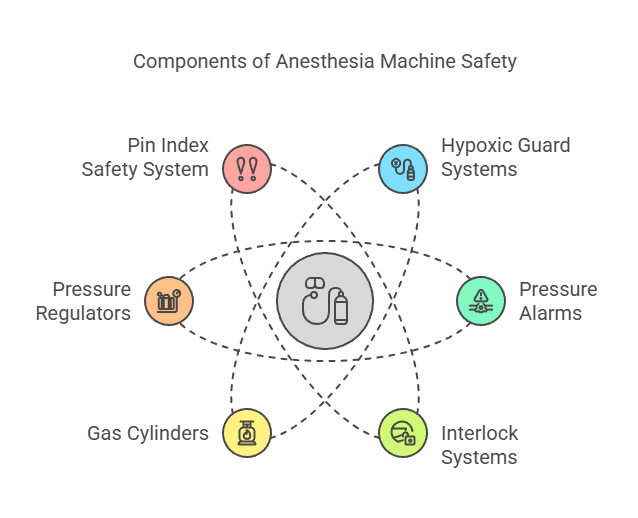

Safety Mechanisms

These machines are equipped with features to prevent errors and protect patients, including:

- Hypoxic Guard Systems: Ensure oxygen levels do not drop below safe thresholds.

- Pressure Alarms: Notify operators of issues such as high or low airway pressures.

- Interlock Systems: Prevent simultaneous activation of multiple vaporizers.

User-Friendly Interfaces

Modern machines feature touchscreens and automated systems, making operation simpler and reducing the likelihood of errors. These interfaces also allow quick adjustments during procedures.

Best Practices for Operating Anesthesia Machines

Pre-Use Checklists

Before each procedure, it is critical to verify the functionality of the machine. This includes:

- Checking cylinder pressures and pipeline connections.

- Ensuring vaporizers are filled and operational.

- Performing leak tests on the breathing circuit.

Routine Maintenance

Regular servicing ensures the longevity and reliability of the machine. Maintenance tasks include:

- Cleaning and replacing filters.

- Verifying the accuracy of flowmeters and monitors.

- Calibrating vaporizers and alarms.

Emergency Protocols

In case of equipment failure, have alternative ventilation systems like a bag-valve mask readily available. Familiarity with backup systems can prevent life-threatening situations.

FAQ’s

What Gases Are Used in Anesthesia Machines?

Common gases include oxygen, nitrous oxide, and air. These are often combined with volatile anesthetic agents such as isoflurane or sevoflurane.

How Do Vaporizers Work?

Vaporizers convert liquid anesthetic agents into a precise gas mixture. Variable bypass systems adjust flow to ensure accurate delivery, regardless of room temperature or pressure changes.

What Are Common Malfunctions and How Are They Addressed?

Common issues include leaks in the breathing circuit, malfunctioning flowmeters, and disconnected gas lines. Regular maintenance and pre-use checks minimize these risks.

How Do Scavenging Systems Protect Healthcare Workers?

Scavenging systems capture excess anesthetic gases, preventing them from being released into the operating room. This reduces occupational exposure and environmental impact.

What Safety Features Are Standard in Modern Machines?

Features like hypoxic guard systems, alarms for pressure deviations, and interlocks for vaporizers are standard in contemporary anesthesia machines.

Is Special Training Required to Operate These Machines?

Yes, operators must be trained in using anesthesia machines, including understanding their components, safety mechanisms, and troubleshooting protocols.

The Role of Anesthesia Machines in Environmental Sustainability

Anesthesia machines are designed with features that minimize their environmental impact. Low-flow anesthesia techniques and gas recycling reduce the waste of anesthetic agents. Scavenging systems further prevent emissions, aligning with sustainability goals in healthcare.

Enhancing Patient Outcomes with Anesthesia Machines

One of the most profound impacts of anesthesia machines lies in their ability to improve patient outcomes through precise sedation and monitoring. These machines not only keep patients comfortable during surgeries but also ensure that their vital functions are carefully managed throughout the procedure. Modern anesthesia workstations have expanded far beyond gas delivery, acting as comprehensive platforms for life support and diagnostics.

Precision in Sedation and Ventilation

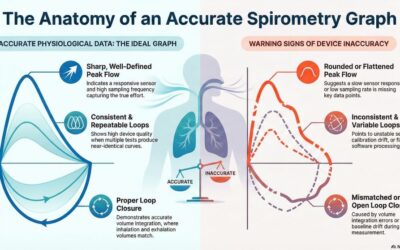

Anesthesia machines are designed to deliver exact amounts of anesthetic agents, avoiding complications associated with over- or under-dosing. Over-sedation can lead to respiratory depression and delayed recovery, while under-sedation may cause awareness during surgery, a traumatic experience for patients. By integrating vaporizers with real-time gas concentration monitors, these machines maintain precise delivery of agents like isoflurane and sevoflurane.

Ventilation management is another critical role. Machines equipped with advanced ventilators provide customizable modes tailored to the patient’s respiratory needs. These include pressure-controlled, volume-controlled, and synchronized intermittent mandatory ventilation (SIMV). Such flexibility is particularly vital for patients with complex conditions like obesity or lung disease, where standard ventilation may not suffice.

Early Detection of Complications

Modern anesthesia machines incorporate robust monitoring systems to detect issues before they escalate. Capnography, which measures end-tidal CO2, ensures effective ventilation and highlights any obstructions or inadequate airflow. Similarly, oxygen saturation monitoring and pressure alarms provide instant feedback, enabling quick interventions in cases of hypoxia or equipment failure.

Postoperative Recovery Benefits

The precision of anesthesia delivery directly influences recovery times. Controlled low-flow anesthesia reduces the accumulation of volatile agents in the patient’s body, minimizing side effects like nausea and prolonged grogginess. Moreover, machines designed to conserve heat and moisture during ventilation help maintain body temperature, reducing postoperative complications such as hypothermia.

Specialized Applications of Anesthesia Machines

While anesthesia machines are commonly associated with operating rooms, their versatility allows them to be used in diverse medical scenarios, including obstetrics, pediatrics, and critical care.

Obstetric Anesthesia

In labor and delivery settings, anesthesia machines are tailored to provide regional anesthesia, such as epidurals or spinal blocks. These techniques require precise control of anesthetic concentrations to avoid systemic effects on both the mother and the baby. Machines equipped with advanced monitoring systems ensure maternal oxygenation and detect fetal distress early, safeguarding both lives.

Pediatric Anesthesia

Caring for pediatric patients presents unique challenges, as children have different physiological responses to anesthesia. Anesthesia machines used in pediatrics are often equipped with neonatal circuits and low dead space components, which minimize the rebreathing of CO2. Additionally, the ability to deliver small, precise doses of anesthetic agents is crucial for this sensitive population.

Critical Care and Emergency Use

In intensive care units, anesthesia machines double as ventilators for patients requiring long-term respiratory support. In emergency situations, their portability and ability to deliver oxygen efficiently can be life-saving. Machines designed for field use, such as those in ambulances or disaster response teams, often include battery-powered functionality and compact designs.

Training and Team Coordination

Effective use of anesthesia machines requires a well-coordinated team and specialized training. While anesthesiologists are primarily responsible for operating these devices, nurses and surgical staff also play pivotal roles in ensuring smooth procedures.

Importance of Training

Operating anesthesia machines is a complex task that requires in-depth knowledge of their components and systems. Training programs for anesthesiologists focus on understanding the mechanics of gas delivery, ventilation settings, and troubleshooting. With modern machines incorporating touchscreen interfaces and digital controls, continuous education is essential to stay updated on technological advancements.

Simulation-based training is increasingly popular, providing hands-on experience with scenarios such as equipment failure or patient decompensation. These programs prepare healthcare professionals to handle real-world emergencies confidently.

Interprofessional Collaboration

In the operating room, teamwork between anesthesiologists, nurses, and surgeons is critical. Nurses often assist by monitoring the patient’s vitals and preparing backup equipment, such as bag-valve masks, in case of ventilation failure. Surgeons rely on anesthesiologists to manage sedation levels and patient stability, enabling them to focus on the procedure.

Open communication within the team is essential to address potential issues swiftly. For example, if a nurse detects an anomaly in the patient’s oxygen saturation, they can alert the anesthesiologist to investigate the cause, whether it’s a kinked breathing circuit or a malfunctioning vaporizer.

Sustainability in Anesthesia Delivery

With growing awareness of environmental issues, the healthcare industry is striving to adopt sustainable practices, and anesthesia machines are no exception. Volatile anesthetics such as isoflurane and desflurane contribute to greenhouse gas emissions, prompting efforts to reduce their environmental impact.

Low-Flow Anesthesia

Low-flow anesthesia techniques significantly minimize waste by using fresh gas flows below the patient’s alveolar ventilation rate. By recycling exhaled gases through carbon dioxide absorbers, this method not only conserves anesthetic agents but also reduces costs. Modern machines with advanced flow sensors ensure accuracy in maintaining low-flow settings without compromising patient safety.

Scavenging Systems

Scavenging systems are integral to minimizing occupational exposure to anesthetic gases and reducing emissions into the atmosphere. These systems capture exhaled gases and vent them outside the building or through filters, ensuring they do not accumulate in the operating room.

Eco-Friendly Innovations

Some manufacturers are developing anesthetic agents with lower environmental footprints and machines that consume less energy. These innovations align with global sustainability goals while maintaining high standards of patient care.

Troubleshooting Common Issues in Anesthesia Machines

Despite their advanced features, anesthesia machines are not immune to technical problems. Prompt identification and resolution of issues are critical to avoid complications during procedures.

Leaks in the Breathing Circuit

Leaks can occur due to disconnections, damaged tubing, or poorly sealed components. Performing pre-use leak tests helps identify vulnerabilities. If a leak occurs mid-procedure, tracing the circuit and re-securing loose connections is essential.

Malfunctioning Vaporizers

Vaporizers are sensitive components that require regular calibration. If a vaporizer fails to deliver anesthetic agents accurately, switching to manual ventilation and administering intravenous anesthesia may be necessary until the issue is resolved.

Pressure Irregularities

Fluctuations in system pressure can indicate blocked pipelines, faulty regulators, or overfilled absorbers. Monitoring alarms and pressure gauges during use can help detect these issues early.

Concluding Thoughts

Anesthesia machines are indispensable tools in healthcare, combining technology and precision to ensure patient safety and optimize surgical outcomes. Understanding their components, functionality, and best practices is essential for any healthcare professional. By adhering to maintenance protocols and staying informed about technological advancements, medical teams can enhance the efficiency and safety of these devices.

Anesthesia Machines Portfolio:

Mindray A9 Anesthesia Machine

The Mindray A9 Anesthesia Machine is expertly designed to streamline clinical workflows while enhancing patient safety. Featuring ICU-level ventilation capabilities, it introduces a revolutionary Volume Exchanger Breathing System that delivers precise and reliable ventilation. With tidal volume settings as low as 5 ml, the A9 ensures exceptional care, particularly for sensitive patient cases.

Mindray A8 Anesthesia System

Combining proven features with cutting-edge technology, the Mindray A8 Anesthesia System ensures intuitive and safe anesthesia management for a broad spectrum of patients. Its innovative electronic platform supports perioperative care, from induction through recovery, driving improved patient outcomes. Equipped with the Volume Exchanger (VE) breathing system, the A8 delivers precise, dependable ventilation tailored to clinical needs.

Mindray A7 Anesthesia Workstation

The Mindray A7 Advantage Workstation integrates electronic fresh gas control technology to optimize flow dynamics and support cost-efficient, low-flow anesthesia delivery. With advanced ventilation modes and an intuitive user interface, the A7 provides reliable care for diverse patient populations, including neonates and bariatric cases.

Mindray A5 Anesthesia Machine

The Mindray A5 Anesthesia System offers advanced digital technology and ventilation modes, with optional integrated gas analysis, capnography, and spirometry loops. Its intuitive touchscreen interface simplifies adjustments, eliminating the need for complex controls or deep menus. Designed for efficiency, the A5 includes built-in safety features, ample workspace, and ergonomic design, enhancing workflow and patient care across varied healthcare settings.

Mindray Veta 5 – Veterinary Anesthesia Machine

The Mindray Veta 5 addresses the growing challenges in veterinary anesthesia with intelligent technology and modern clinical practices. Featuring advanced ventilation modes and an integrated design, the Veta 5 prioritizes safety for both animals and veterinarians, redefining the standards of veterinary anesthesia.

Mindray Veta 3 – Veterinary Anesthesia Machine

The Mindray Veta 3 Veterinary Anesthesia Machine combines a sleek, integrated design with advanced safety features, ensuring optimal care for animals while supporting veterinarians in delivering precise and effective anesthesia management.